Construction and mechanics

Main article: Violin construction and mechanics

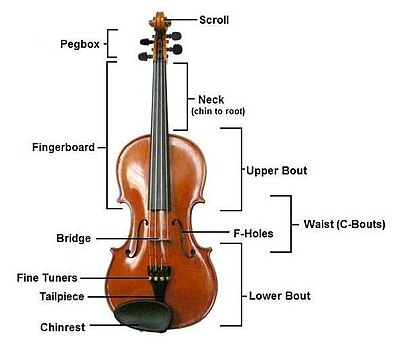

A violin typically consists of a spruce top (the soundboard, also known as the top plate, table, or belly), maple ribs and back, two endblocks, a neck, a bridge, a soundpost, four strings, and various fittings, optionally including a chinrest, which may attach directly over, or to the left of, the tailpiece. A distinctive feature of a violin body is its hourglass-like shape and the arching of its top and back. The hourglass shape comprises two upper bouts, two lower bouts, and two concave C-bouts at the waist, providing clearance for the bow.

The voice of a violin depends on its shape, the wood it is made from, the graduation (the thickness profile) of both the top and back, and the varnish that coats its outside surface. The varnish and especially the wood continue to improve with age, making the fixed supply of old violins much sought-after.

The very great majority of glued joints in the instrument use animalhide glue for a number of reasons: it is capable of making a thinner joint than most other glues, it is reversible (brittle enough to crack with carefully applied force, and removable with warm water) when disassembly is needed, and since fresh hide glue sticks to old hide glue, more original wood can be preserved when repairing a joint. (More modern glues must be cleaned off entirely for the new joint to be sound, which generally involves scraping off some wood along with the old glue.) Weaker, diluted glue is usually used to fasten the top to the ribs, and the nut to the fingerboard, since common repairs involve removing these parts.

The purfling running around the edge of the spruce top provides some protection against cracks originating at the edge. It also allows the top to flex more independently of the rib structure. Painted-on faux purfling on the top is usually a sign of an inferior instrument. The back and ribs are typically made of maple, most often with a matching striped figure, referred to as flame, fiddleback, or tiger stripe.

The neck is usually maple with a flamed figure compatible with that of the ribs and back. It carries the fingerboard, typically made of ebony, but often some other wood stained or painted black. Ebony is the preferred material because of its hardness, beauty, and superior resistance to wear. Fingerboards are dressed to a particular transverse curve, and have a small lengthwise "scoop," or concavity, slightly more pronounced on the lower strings, especially when meant for gut or synthetic strings.

Some old violins (and some made to appear old) have a grafted scroll, evidenced by a glue joint between the pegbox and neck. Many authentic old instruments have had their necks reset to a slightly increased angle, and lengthened by about a centimeter. The neck graft allows the original scroll to be kept with a Baroque violin when bringing its neck into conformance with modern standards.

The bridge is a precisely cut piece of maple that forms the lower anchor point of the vibrating length of the strings and transmits the vibration of the strings to the body of the instrument. Its top curve holds the strings at the proper height from the fingerboard in an arc, allowing each to be sounded separately by the bow. The sound post, or soul post, fits precisely inside the instrument between the back and top, below the treble foot of the bridge, which it helps support. It also transmits vibrations between the top and the back of the instrument.

The tailpiece anchors the strings to the lower bout of the violin by means of the tailgut, which loops around an ebony button called the tailpin (sometimes confusingly called the endpin, like the cello's spike), which fits into a tapered hole in the bottom block. Very often the E string will have a fine tuning lever worked by a small screw turned by the fingers. Fine tuners may also be applied to the other strings, especially on a student instrument, and are sometimes built into the tailpiece.

At the scroll end, the strings wind around the tuning pegs in the pegbox. Strings usually have a colored silkwrapping at both ends, for identification and to provide friction against the pegs. The tapered pegs allow friction to be increased or decreased by the player applying appropriate pressure along the axis of the peg while turning it.

Strings

Main article: strings section of Violin construction

Strings were first made of sheep gut (commonly known as catgut), or simply gut, which was stretched, dried, and twisted. Modern strings may be gut, solid steel, stranded steel, or various synthetic materials, wound with various metals, and sometimes plated with silver. Most E strings are unwound, either plain or gold-plated steel.

Strings have a limited lifetime. Apart from obvious things, such as the winding of a string coming undone from wear, players generally change a string when it no longer plays true, losing the desired tone. String longevity depends on string quality and playing intensity.

Pitch range

The compass of the violin is from G3 (G below middle C) to C8 (the highest note of the modern piano.) The top notes, however, are often produced by natural or artificial harmonics. Thus the E two octaves above the open E-string may be considered a practical limit for orchestral violin parts.

Acoustics

Main article: Sound production (string instruments)

The arched shape, the thickness of the wood, and its physical qualities govern the sound of a violin. Patterns of the node made by sand or glitter sprinkled on the plates with the plate vibrated at certain frequencies, called Chladni patterns, are occasionally used by luthiers to verify their work before assembling the instrument.

0 comments:

Post a Comment